Most of us learned in high school chemistry that liquids conduct electricity. When liquid touches a powered MacBook the results can be damaging. While the device may appear “off,” it’s actually just in a low-power state, waiting to be activated. When liquid makes contact with an active circuit, it causes fizzing (you might even hear it) and leads to corrosion in the circuit’s conductive parts. The higher the voltage, the faster this process happens—this is why high-voltage components, like the backlight driver chip producing up to 50 volts, is usually the first to fail when a MacBook is exposed to liquid.

Example

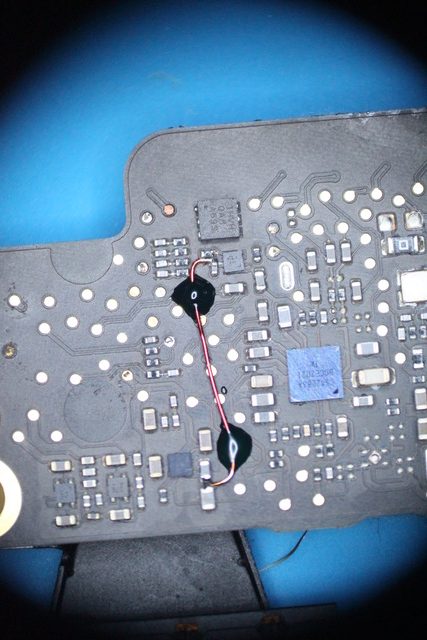

Take, for example, a MacBook that got wet and wouldn’t turn on. Liquid had seeped onto the logic board – Apple’s term for the motherboard. The result? Electrolysis (or corrosion), which created short circuits and damaged the circuit tracks and solder connections and left the visible mess shown in the photo. This allowed excessive voltage and current to flow incorrectly, leading to further component damage.

Now, here’s where the cost-saving difference comes in. If you take this MacBook to Apple or an authorized reseller, their first step is to check for liquid damage. If they find any, their strict policy requires them to replace the entire logic board, keyboard and trackpad. This repair can cost between 80-90% of the price of a brand-new MacBook! But at UK Mac Repair, we do things differently. Instead of replacing entire components unnecessarily, we only repair what is broken. This approach means you pay just 25-50% of the cost compared to Apple’s prices.

In the close-up photo, you can see the damage caused by corrosion under the components. A shiny round metal pad and its connecting track have been eaten away leaving a dull circle. Tracing the damage further inside the logic board is a challenge, especially without Apple’s proprietary circuit diagrams, but it’s not impossible for a skilled electronic engineer who understands circuit design. Apple replaces a logic board for far less damage than this yet I frequently repair far worse.

The next photo shows the same region of the logic board after repair. I replaced the damaged components and restored the internal track with a 10mm long insulated copper wire, secured with heat-resistant adhesive. After completing the repair, the board was cleaned in an ultrasonic bath, baked at 120°C to dry, and thoroughly tested before being returned to the customer.

This method ensures that no money is wasted. Your data stays intact and, most importantly, no logic board needs to be replaced. By opting for true repair you save money but you save the environment the cost of a new logic board being manufactured—no 300kg of greenhouse gases released to damage the ozone layer.

With true repair, you save money, protect your data and help the planet—it’s a win all around.